Digital product passport

We provide your products quickly and easily with a digital nameplate and unique identification in accordance with IEC 61406.

Suppose you would like to provide your data according to the AAS (Asset Administration Shell) or VDI 2770 in the future. In that case, we are the optimal partner for you.

create a digital nameplate according to IEC 61406

With this application, you can create your customised digital rating plate with an IEC 61406-compliant identification link in just a few minutes. The tool supports you with the following features:

- Generate your QR code

- Creation of your digital nameplate

- Upload your product documents and certificates

- Upload your product photos and company logos

Test the nameplate creator in a free demo version.

Please note our privacy policy.

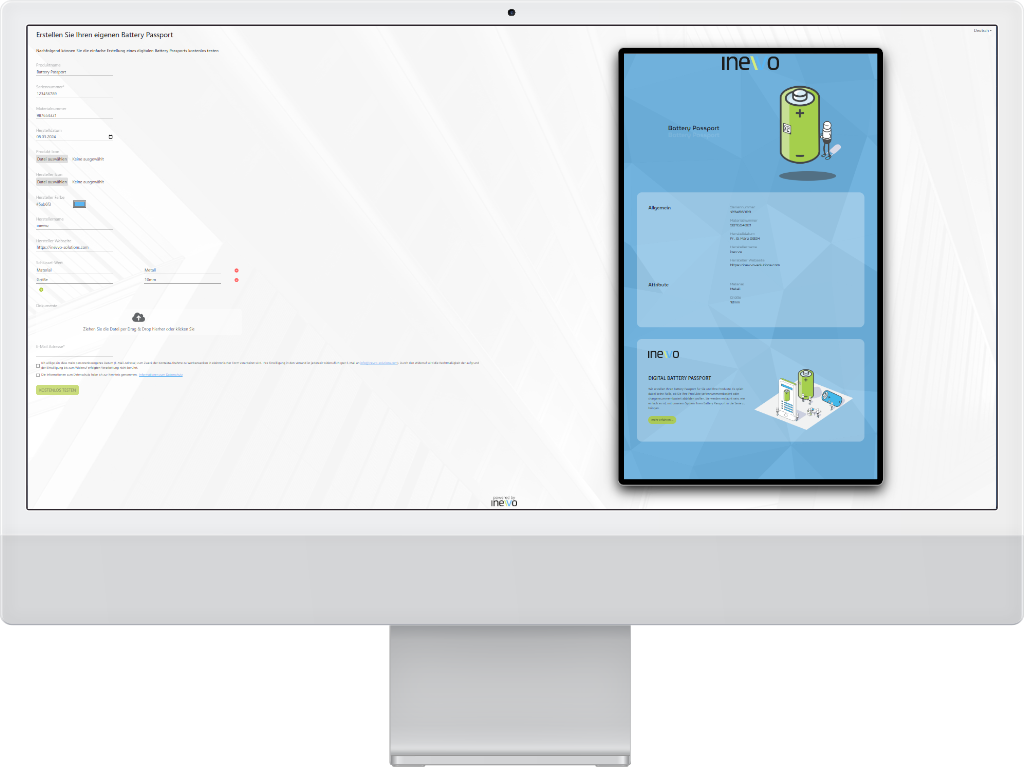

Digital battery passport

We create your Battery Passport for you and your products. It does not matter whether you want to map your products based on serial numbers or batch numbers. You will be amazed at how easy it is with our system to bring your Battery Passport into series production.

create a digital battery passport according to IEC 61406

With this application, you can create your customised digital battery passport with an IEC 61406-compliant identification link in just a few minutes. The tool supports you with the following features:

- Generate your QR code

- Creation of your digital battery passport

- Upload your product documents and certificates

- Upload your product photos and company logos

Test the digital battery passport in a free demo version.

Please note our privacy policy.

Asset management

With  , you manage all your assets (from the drilling machine to your coffee machine, to the production line) quickly and easily.

, you manage all your assets (from the drilling machine to your coffee machine, to the production line) quickly and easily.

Digital maintenance tool

You can now confidently leave the planning, documentation and execution of your maintenance to  .

.

Digital plant construction

You build your plant, and  takes care of the documentation. Save time and nerves during plant qualification.

takes care of the documentation. Save time and nerves during plant qualification.

Digital documentation

We help you create your digital documentation

With CONEXO from inevvo, we have found a solution that drives us forward in all areas of the company. In addition, Kevin and his team are great to work with.

Stefan Blank

Service Pharma Development

BWT Aqua

CONEXO from inevvo solutions offers us the solution to comply with the prescribed maintenance intervals of our operating equipment. Through the CONEXO platform, we get traceable documentation of our performed maintenance, and the team is available to us with advice and support.

Marco Kolar

Maintenance Planner

GEMÜ